Hybrid Street Turbo Project

Introduction

I am increasingly frustrated by the limited availability of “small” turbochargers. On one end, there are pricey high-quality units from the big names; on the other, there are inexpensive, untested knockoffs from China. The mid-range options are scarce. If I were building a track or drag car, I would have no issue investing in a premium brand. However, for a moderate street build, their prices are difficult to justify, particularly given their lack of serviceability. My objective for this project is to create an efficient and cost-effective turbo for a street build. I plan on building a hybrid turbocharger and will use my vehicle to test various component combinations and setups. The goal is to develop a responsive turbo that can hold power to redline. The initial horsepower target is 300AWHP, with the intention of upgrading the turbo to increase power at a later time.

Vehicle Description

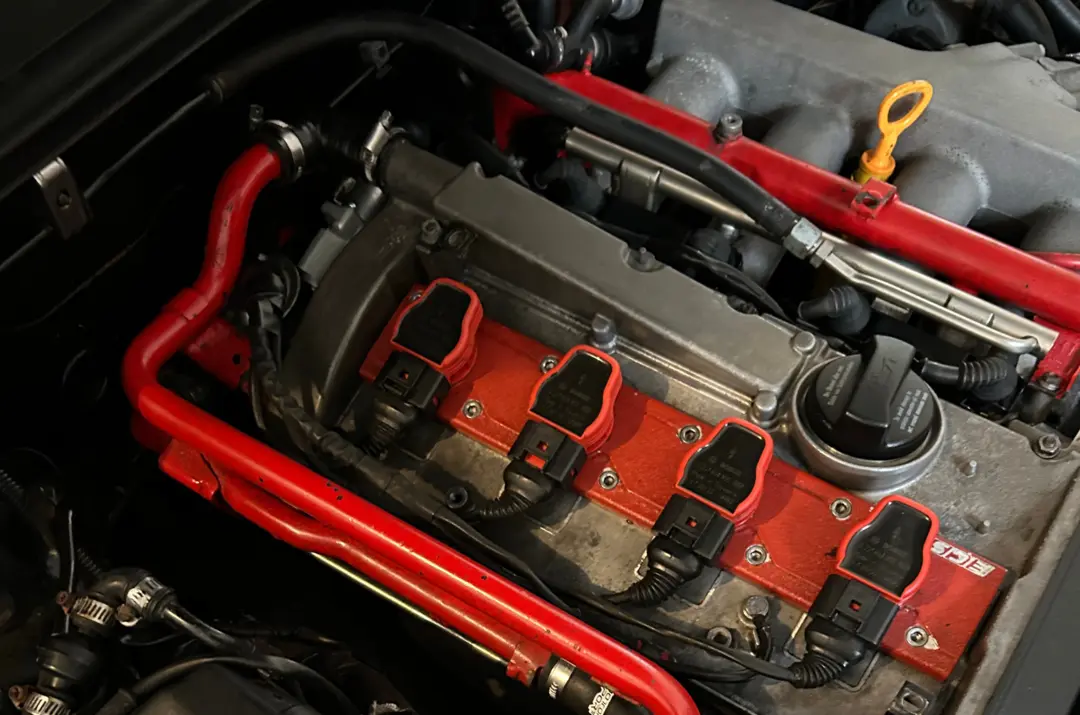

I will be using my 2002 Audi A4 Quattro 1.8t as the test platform. The car comes equipped with a 5-speed transmission and has several modifications already installed. These include larger 82.5mm forged pistons, H-beam forged connecting rods, upgraded rod and main bearings, ARP fasteners, a drop-in high-flow air filter, a Milltek exhaust system, and Supertech valvetrain upgrades. Unfortunately, the car still retains the factory K03S turbocharger, a relatively small turbocharger commonly found on older Audi and Volkswagen models. While it provides instant boost, it is notably inadequate in terms of power output, especially beyond 5500 rpm. In my opinion, Audi should have equipped the vehicle with a larger factory turbocharger. This sentiment is echoed by many within the 1.8t A4 community, who agree that Audi’s choice of a K03 was a misstep. My objective is to rectify this error by identifying and installing a suitably sized turbocharger. This will be achieved by testing various combinations of compressor and turbine wheel sizes, housings, bearings, and materials.

Build Plans

For those acquainted with the 1.8t platform, the choice not to opt for a K04 turbocharger, despite it being the recommended upgrade, may raise questions. If the vehicle featured a transversely mounted 1.8t engine, the K04 would be a viable consideration due to its compatibility with existing turbo components. Unfortunately, the longitudinal engine has fewer options available. Additionally, the factory turbo manifold of the longitudinal 1.8t engine constrains the turbine side of the turbo, thereby limiting peak horsepower, even when utilizing a larger compressor. The K04 turbo, when paired with supporting modifications, makes approximately 240whp, whereas the K03S makes around 210whp. In my opinion, the performance gain does not justify the investment.

I will start the project with an internal wastegate (IWG) turbocharger, comparable in size to a Garrett GT25/28. The turbocharger will use a T25 flange for the turbine inlet. The T25 flange gives me a lot of flexibility in terms of compatible housings and manifolds. I intend to convert the wastegate from an internal to an external configuration, as external wastegates (EWGs) are preferable for performance-oriented builds. Additional information on this topic can be found here. I will conduct tests and collect data on the turbo’s performance once the car has been modified and tuned.

Upon completion of the initial tests, I will make some upgrades to the turbocharger. Initially, the focus will be on improving component materials and design. Subsequently, I will increase the compressor wheel size and upgrade the rotating assembly components. I aim to increase both the peak HP number and the efficiency of the turbo without increasing the turbine wheel size. After the upgrades are complete, comprehensive tests will be conducted on the new setup. The data will be collected and posted here.

The last thing I have planned is to transition to a larger framed turbocharger, likely a T3 flanged unit, comparable in size to a Garrett GT3582. This time I want to increase the horsepower by a decent amount. Opting for a larger turbocharger will provide access to a broader range of components and configurations. This includes twin-scroll housings, which offer superior efficiency compared to single-scroll designs. However, this consideration is for a later stage; the current focus remains on the T25 flanged unit.

Final Note

This journal serves as a method for documenting my progress in the development and testing of turbochargers. It is intended to be a resource for individuals interested in similar vehicle modifications. The objective is to provide precise data on these turbochargers, rather than merely estimated crank horsepower figures for various engine displacements. Please be aware that, as a human, errors and misinterpretations may occur. Should you identify any inaccuracies, you are encouraged to leave a comment or contact me directly. I am receptive to all constructive feedback. With that note, I am eager to commence this endeavor. Thank you for reading, and please look forward to my subsequent posts.