External vs Internal Wastegates: Which One Should You Choose?

Introduction

Wastegates are essential for turbocharged engines, they play a critical role in regulating boost pressure. It is widely recognized that there are two types of wastegates: internal (IWG) and external(EWG). You might be wondering which one is a better option. Like many things in the automotive industry, there’s a time and place for each one. We will discuss when you may want to use one over the other and the advantages of doing so. Before we get into that, let’s first go over wastegates and some differences between IWGs and EWGs.

What Is a Wastegate

Definition & Purpose

A wastegate is a spring-loaded valve designed to regulate boost pressure. This is achieved by redirecting a portion of the exhaust flow away from the turbocharger’s turbine wheel once a specified amount of boost is attained. By directing exhaust flow around the turbine, the turbine wheel speed can be controlled, thereby limiting the boost pressure generated by the compressor. There are various reasons why limiting boost may be desirable. For one limiting boost can increase the longevity of the turbo and engine. Another reason is to prevent component failure due to over-speeding. Over-speeding occurs when the turbo operates outside the borders of its compressor map (efficiency map) for an extended period. This results in the turbine shaft speed and temperature exceeding the limits of the turbocharger. Numerous complications may arise when turbine shaft speeds exceed their designated thresholds. For example, the turbine shaft could experience complete failure, the compressor wheel could be damaged, the turbocharger bearing could malfunction, or the turbo could be starved of oil. Over-speeding can cause your engine to overboost. Extended periods of overboosting can be detrimental to an engine and typically degrades performance. It can also lead to rapid engine overheating and damage internals. The difference between the two types of wastegates (internal and external) pertains to the location of the valve/gate. One type is located within the turbine housing of the turbocharger. The other is usually located on the turbo manifold or the exterior of the turbine housing.

How It Works

Wastegates are not as complex as most think. Think of it as a door or valve that opens when a predetermined amount of boost pressure pushes against it. Both types of wastegates are comprised of two main components, the diaphragm/actuator, and the valve or gate. Out-of-the-box the wastegate uses an innerspring installed in the actuator to control boost pressure. The tension from the spring keeps the gate/valve shut. As the turbocharger spins faster, the boost pressure increases. This boost pressure will push against the actuator’s innerspring. As this pressure approaches the desired boost pressure (determined by the wastegate spring or electronic solenoid) the valve will open. This allows some of the exhaust gas to bypass the turbine, effectively slowing the speed of the turbo. Slowing down the turbo limits the amount of boost pressure it can make, which keeps it from overboosting. There are some key differences between the design of internal and external wastegates which we will discuss next.

Internal Wastegates

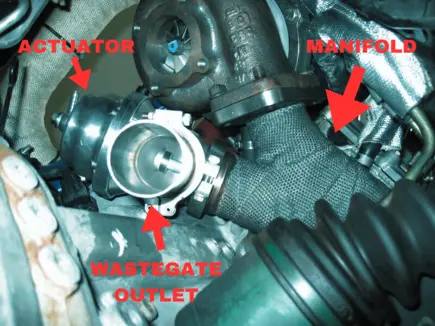

Internal wastegates are primarily found on OEM applications and factory turbos. Car manufacturers love to use them due to their cost-effectiveness, low noise, and compact size. They get their name from the fact that the wastegate door is located inside of the turbine housing A rod connects this door to the actuator which is usually bolted to either the compressor or turbine housings. A boost signal line is run from a port on the actuator to a tap located on the compressor housing of the turbocharger. The line feeds the actuator charged-air coming out of the turbo’s compressor. When the boost pressure exceeds the resistance of the actuator spring, it compresses the spring. This action moves the connected rod, resulting in the opening of the valve. This causes some exhaust flow to bypass the turbine and move directly into the downpipe or catalytic converter. Some factory turbo systems use an electronic solenoid to control when the wastegate opens. The solenoid monitors the boost pressure by using data supplied by the mass airflow (MAF) sensor. Upon hitting the designated boost pressure, the solenoid will signal the wastegate actuator, instructing it to open the valve. Although they are less customizable than their external counterparts, there are a few ways to adjust when the valve opens on an internal wastegate. Some internal wastegates have an adjusting jam nut on the rod that links the actuator to the gate. Turning this nut can increase or decrease tension on the actuator spring, giving you 2-3 PSI of adjustment. Aftermarket adjustable IWGs are available, these units offer better efficiency (especially at higher boost levels). Another option is to make use of an electronic solenoid. You can program the solenoid to open the wastegate at a higher boost pressure than the one set by the actuator spring. One last thing before we move on to external wastegates. Now that we have covered some of the basics of internal wastegates, let’s move on to discussing the external ones.

External Wastegates

External wastegates are generally found on high-performance vehicles or modified vehicles designed for racing. External wastegates are not as compact as internal ones, and they usually require a manifold that has a wastegate port. This is why most automotive manufacturers have moved away from this type of wastegate. EWGs control boost much in the same way as the IWGs do. When a predetermined boost pressure limit is reached, the wastegate valve opens allowing some of the engine exhaust to bypass the turbine. This keeps the turbine from spinning faster, ultimately limiting boost. Unlike IWGs, EWG setups let you control the path of the bypassed exhaust via a dump/screamer pipe. A dump pipe carries the bypassed exhaust into the atmosphere or back to the exhaust system. Most racing teams and street tuners prefer the bypassed exhaust be vented into the atmosphere. Venting into the atmosphere can drastically shorten the exhaust path, increasing performance(due to less backpressure) while decreasing costs. This is why setups where the dump pipe exits the hood are so popular it’s cost-effective (uses very little material) and easy to design (at a basic level). Unfortunately, hood exit setups are not operable during rain or snow conditions. If this is a concern, you can opt to have the dump pipe feed back into the exhaust system. Routing the bypassed exhaust through the catalytic converter is ideal for those looking to be compliant with emission laws. A specially designed downpipe is usually used with this type of setup. In terms of adjustability, External wastegates have a few more options. You can control; where the EWG will be placed (manifold or turbine housing exterior), the size of the wastegate, the actuator spring(both in size and strength), and where the bypassed exhaust is vented. EWGs can also make use of an electronic solenoid to control when the valve/door opens. Most tuners recommend using electronic solenoids due to their superior control, efficiency, and response. External wastegates can be water-cooled, further increasing their efficiency and reliability, making them extremely beneficial to high-performance and racing applications. External wastegates are responsible for that signature “whistle” sound when you’re on the throttle. Hopefully, you now have a basic understanding of both external and internal wastegates, we will now talk about which one is better.

Which is Better?

In terms of efficiency and effectiveness, external wastegates reign king. This is the reason why you will find EWGs on most performance-focused builds. However, they are not without their flaws. If your main concern is cost, compactness, or emissions compliance, then an IWG would be a better choice. Externally Wastegated (EWG) systems possess a distinct advantage over Internally Wastegated (IWG) systems due to their proficiency in mitigating boost creep efficiently. IWGs are prone to boost leaks due to their design. Boost creep occurs when the wastegate can’t flow enough air around the turbo to slow it down. This causes the boost pressure to slowly rise past the intended boost limit. Boost creep can cause the block to overheat and severely damage engine internals. The size of the wastegate port in the turbine housing is a limiting factor for IWGs and can be a problem at higher boost levels. This is the reason why EWGs are chosen for high-boost applications. They do their job much more efficiently, making them the better choice for those running 20+ PSI. I have included a list detailing the advantages and disadvantages of each type of wastegate below.

Advantages of External Wastegates

Most external wastegates come with adjusters from the factory, allowing for 4-5 PSI of change in tension. External wastegates are available in multiple valve sizes (38mm, 44mm, etc), allowing you more adjustment with your setup. EWGs use larger valves giving them better response and performance. They generate less backpressure in the turbine housing and manifold, which helps performance. Additional valves can be added (multiple EWGs) giving you further optimization of flow. EWGs allow you to further improve flow through custom fabrication of your exhaust paths (manifold, dump pipe). EWGs control boost more efficiently and have better heat management due to design & optional water cooling. EWGs are easy to service. Replacement components are readily available. EWGs come in a variety of colors allowing you to further customize the look of your engine bay.

Disadvantages of External Wastegates

EWGs are not as compact as IWGs and often require additional parts and plumbing. This can add complexity and increase costs. Most EWG setups do not use a catalytic in the exhaust path, this can make passing emissions checks difficult.

Advantages of Internal Wastegates

IWG setups don’t require as many parts as their EWG counterparts, making them less complex and lower in cost. IWG setups take up a lot less space in the engine bay. IWGs are designed to be compliant with most emission laws. IWG setups are easier to hide in the engine bay and make less noise, which is perfect for stealth/sleeper builds.

Disadvantages of Internal Wastegates

IWGs are not designed for high-boost applications. They are prone to boost creep (damages the engine). The valves/gates are smaller than those in EWGs, this limits their flow capability. The gate and turbine housing must match the engine and boost pressure well. On IWGs that don’t use an electrical solenoid, the gate will open 3-4 PSI before the intended boost pressure is hit. IWGs don’t allow you to increase the size of the valve or gate (flapper). IWGs do not respond to changing boost pressures very quickly. Bypassed flow from IWG can cause turbulence in the turbine housing which generates additional backpressure and turbo lag.

Conclusion

To summarize, choose the wastegate that best suits your platform. If going for pure performance, EWGs are the clear winner. They are more efficient (especially at higher boost levels), offer better performance, offer more adjustability & customization, and reduce the chances of boost creep. However, they’re not ideal for every application. I would opt for an IWG if: I am working with a limited budget, if emission compliance is a prime concern, if I lack the engine space for an EWG, if I am upgrading the vehicle using bolt-ons, or if I want my vehicle to appear stock (stealth build). When considering a wastegate I recommend first asking yourself how much boost you intend to make. If you plan on running 25+ PSI I would opt for an EWG. The higher the boost level, the more advantageous EWGs are. At higher boost levels IWGs require serious modification to match an EWG’s efficiency. The next question I’d ask myself is, what kind of driving the vehicle will see? If it’s racing-oriented or high-output driving, I would choose an EWG. Conversely, an IWG would be more suitable for a daily driver in regions with stringent emission regulations. Answering these two questions should give you an idea of which type of wastegates would be better for your build. If you still have no idea which one to pick, ask your tuner or someone with experience tuning your vehicle. They should be able to steer you in the right direction. If you’re unsure where to start, feel free to message me I can certainly help you out. I have the ordered parts for the prototype, and they are on the way. Stay tuned for my next post, and thanks for reading.